By: CIFAR

1 Jan, 2017

So one day Heffernan walked 10 miles to the nearby town of Nelson and negotiated a contract with a jam factory owner to buy the fruit. Then he used the contract as collateral to buy a used truck. After that he walked home to tell his father about the deal. He couldn’t drive the truck back – because at 13 he was too young to drive and didn’t have a license.

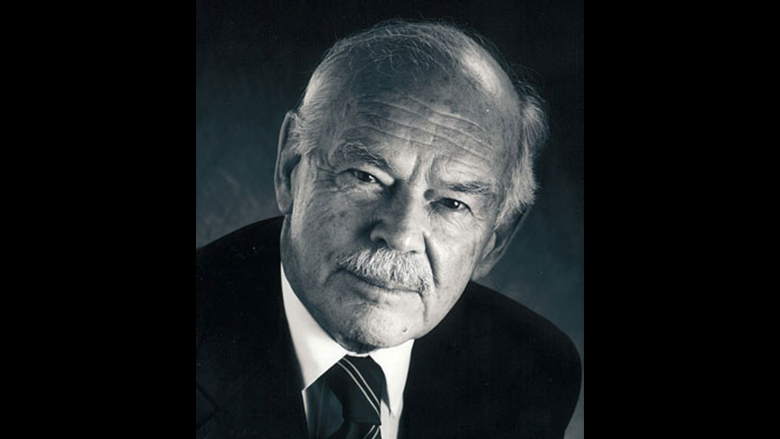

This entrepreneurial spirit, combined with a scientific mindset and a constant desire for greater efficiencies, eventually helped Heffernan to build an international steel company, and in the process transform the global steel industry. He says a similar dedication to applying research lessons to real-world transformation is what attracted him to CIFAR.

Heffernan is the engineer and businessman who founded the Co-Steel empire, and whose technological innovations helped create the “mini-mill” revolution in steel making. He is also a long-time supporter of CIFAR, both as a donor and past director, becoming involved in 1985 shortly after discussing the Institute with CIFAR founder Fraser Mustard.

“I remember meeting Fraser and we hit it off right away. I was always very interested in the scientific side of things, and then Fraser came along, and I found he was very compatible with some of my thinking about industry and about science. So we went from there.” Heffernan says.

Heffernan was born in Edmonton in 1919, but moved to the Kootenay region of British Columbia with his family as a child. The area they lived in was a mining region, and the family was involved in the industry – his grandfather as a mine owner and his father as a broker in nearby Kaslo.

Heffernan remembers that in front of his grandfather’s mine was a big, gold-flecked rock that advertised the quality of the ore. Heffernan suspects that his grandfather had fired some gold dust into the rock with a shotgun. “My grandfather was a great promoter,” he says.

As a child, Heffernan went around to mines with a friend of his father’s, and learned to judge ores so well that he won a five-dollar prize in a contest, competing against adults including prospectors and other professionals.

On top of exciting an interest in mines and metal, Heffernan says, his childhood in the Kootenays helped hone two qualities that would work well for him as a businessman – entrepreneurialism and risk-taking. He gathered and sold huckleberries and seeds, collected beer bottles, raised rabbits, and at 16 he even made a deal with a retired boxing pro. The deal was that the pro would charge 25 cents a match for boxing fans to watch him fight in exchange for lessons. To relax, he climbed mountains and swam in glacial lakes. “I’m afraid I like risk,” he says.

At the University of Toronto he studied Metallurgical Engineering and joined the Canadian Officers Training Corp (COTC). Before writing his final exams he was granted his degree and became an Officer in the Royal Canadian Engineers and trained many platoons of engineering troops.

“With the war over, a fellow officer and I were playing cribbage and bored out of our minds. And he said, ‘A lot of my platoon are going back to university.’”

Heffernan got leave and visited the engineering department at the University of British Columbia. Heffernan’s friend was right. With so many men serving overseas the university was understaffed, and desperately trying to prepare for the influx of ex-servicemen they knew would be enrolling soon. The university hired Heffernan, arranging for him to get an immediate discharge.

“I met Dr. Frank Forward, who was the head of the department, and he put his arms around me and said, ‘God, am I glad to see you. I’ve got all these guys coming back, and I’m the only person in the department.’”

Heffernan worked there as a teacher and doctoral candidate, and also audited business classes. Eventually, he decided to leave the university for private industry, heeding the advice of a professor that someday he’d make an excellent CEO. He took a job as a metallurgist at the Western Iron & Steel Foundry.

“It was run by a bunch of Scots, tough guys, and it was all a black art. The melter would judge the temperature of the steel by eye, depending on the colour of the stream. And of course the colour would change with the light. If it was a bright sunny day he’d get one reading. If it was a dull, rainy day he got a different reading. They were getting a lot of problems with the scrap castings.”

Heffernan convinced a skeptical management to buy an optical pyrometer, which could give very accurate temperature readings. The pyrometer eliminated the casting problems, and Heffernan instituted a number of other changes that improved operations at the plant. But it wasn’t always easy to convince the superintendent. “He was this old, dour Scot. ‘It’ll ne’er work, lad. Ne’er work.’ That was his usual response to me when I proposed a change. I got my first ulcer fighting with old Jimmy.”

The experience, though, was excellent, and proved that a more scientific approach to steelmaking could pay off. “I remember my professors had talked about the art and science of steelmaking. My objective was to get rid of the ‘art’,” Heffernan says.

When Heffernan entered the industry, most steel was made in large blast furnaces and 1,000-ton open hearth furnaces. The molten steel was cast into large ingots of up to 30 tons and rolled in massive mills to produce steel plates, coils and bar products.

In 1954 Heffernan built a mill in Edmonton, designed around 30-ton electric arc furnaces and continuous casting of billets to be rolled directly into finished product. In 1963 Heffernan sold the plant to the Steel Company of Canada based in Hamilton, Ontario (STELCO) and built another company, Lake Ontario Steel Co. (LASCO) in Whitby to compete with STELCO using electric arc furnaces and continuous casting. That made it the first true “mini-mill,” according to industry historian John Stubbles, and helped usher in a new era in steelmaking.

Heffernan continued to develop the technology and open more plants, creating Co-Steel International in 1970, which he developed into a mini-mill empire with plants in England and the United States.

Over the following decades the lower-cost, more flexible and less-polluting mini-mill technology was adopted around the world, and helped to drive older and lower-efficiency plants out of business. Today about 33 per cent of the steel produced in the world uses electric arc furnaces.

Heffernan’s career earned him a spot in the Canadian Science Hall of Fame and American Metal Market Hall of Fame in 2014. Heffernan holds several awards and designations, including the AIME Benjamin E. Fairless Award for leadership in new design and steel-making techniques; the Ontario Professional Engineering Gold Medal, Officer of the Order of Canada, the U.K.’s Institute of Metals Bessemer Gold Medal for technological innovation in the steel industry, Association for Iron & Steel Technology’s Tadeusz Sendzimir Memorial Medal and AIME Honorary Member for his commitment to advancing the technologies of electric arc furnace steelmaking and continuous casting, and was also inducted into the Canadian Science and Engineering Hall of Fame, and Canadian Business Hall of Fame.

Impressed by Fraser Mustard’s vision for a Canadian institution for advanced research, Heffernan joined CIFAR’s board of directors in 1985. His guidance helped to shepherd the Institute through its early years as the Institute sought financial stability. A turning point for CIFAR occurred when he and Dr. Gerry Hatch, Founder of Hatch Engineering, recruited David Johnston, now the Governor General of Canada, to become Chairman of CIFAR. Heffernan and Hatch each gave CIFAR $1 million for working capital.

One of his many research interests was the work being done on early childhood development by Clyde Hertzman and others in the CIFAR program now called Child & Brain Development. In recent years Heffernan has also become interested in CIFAR’s new program in Bio-inspired Solar Energy, headed by Dr. Ted Sargent of the University of Toronto.

“Ted’s a risk taker, and I think that’s an essential part of his job,” Heffernan says. “What they’ll learn in this programme has tremendous potential. With a better understanding of photosynthesis they can come up with some important answers. Every kid learns about photosynthesis, but nobody knows quite how it works.”

“Jerry’s scientific outlook and business knowledge have made him a huge asset to CIFAR”, says Alan Bernstein, CIFAR’s President and CEO. “He was an early and very important supporter of the Institute, and we would never have achieved what we have without him. Jerry truly understands the importance of scientific research, and how it can have positive impacts on the world. We’re fortunate to have his support and guiding hand for many years,” Bernstein says.

CIFAR is a registered charitable organization supported by the governments of Canada and Quebec, as well as foundations, individuals, corporations and Canadian and international partner organizations.